Cyclo Centrifuge Drives

Cyclo Centrifuge Drives Applications

Cyclo speed reducers and gearboxes have several advantages over traditional parallel and in-line gearing for centrifuge drives. This is because the cycloid gearbox design is well suited for high speed, high torque operation that needs to be perfectly balanced and vibration-free.

There are several features of Transcyko cyclo centrifuge drives that make them the best choice for centrifugal applications:

- Compact Circular Design

- Large Single-Stage Reduction Ratios

- Shock Overload Resistance

- High Output Torque Capability

Compact Circular Design

Vibration and instability are causes of failure in centrifuges. These need to be minimized as much as possible. The compact circular design of cyclo centrifuge drives has two significant advantages over traditional gearboxes.

- Balanced Design

- Shorter Length

The flatter, circular arrangement of the gears compared to traditional gearboxes makes the cyclo drive naturally balanced and stable in operation, reducing noise and vibration.

Drive shafts are shorter and lighter to achieve the same output torque as a larger non-cyclo gearbox. The longer drive shafts of non-cyclo gearboxes mean that gear and shaft components have to be much more heavily built to resist lateral forces and maintain balance.

Large Single-Stage Reduction Ratios

Our Cycloidal Derivative TZ-S cyclo centrifuge drives are designed to achieve single stage reduction ratios from 6:1 to 87:1. This makes them suitable for both low speed and very high speed centrifuges in a single step without the need for additional stages.

Shock Overload Resistance in Cyclo Centrifuge Drives

The balanced, compact design of cyclo drives makes them very suitable for resisting shock loadings that can be generated by centrifuges. Because cyclo gears are held in position from all sides, shock loadings are distributed evenly throughout the drive and not focused on individual components. This significantly reduces the risk of component failure compared to other types of drive.

High Output Torque Capability

Cyclo drives are extremely durable and reliable because of the way forces are shared evenly between components in a balanced system. This enables us to build them with very high output torque capabilities.

We offer cyclo centrifuge drives capable of outputs of 30-40,000Nm as standard. Our in-house design team can build drives with higher torque capabilities to meet any customer requirement.

Cyclo Centrifuge Drive Applications

Cyclo centrifuge drives are very versatile and can be employed cost-effectively in any centrifugal application. This is primarily because of their high speed, high torque capabilities and the wide range of ratios that they offer, but they also have other excellent features.

Because cyclo centrifuge drives are compact and self-contained they can easily be built as sealed units, and the reduced vibration and noise makes them quieter and less likely to leak than other types of drive.

This makes cyclo centrifuge drives the best choice for food-grade, chemical and pharmaceutical businesses where lubricant contamination and leaks are completely unacceptable.

Globally our customers employ Transcyko centrifuge drives in a wide range of operations and applications:

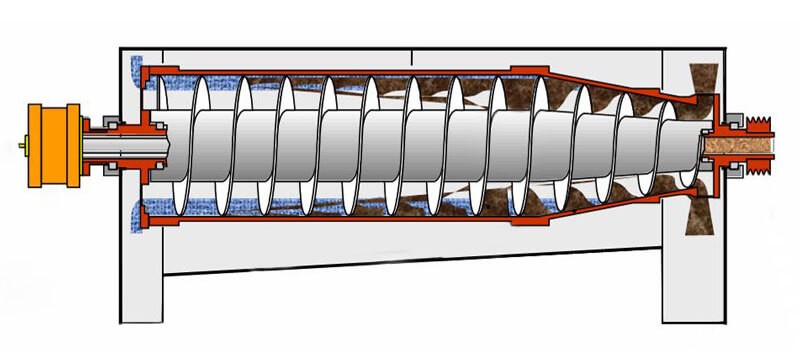

- Centrifuges with a Screw Conveyor for Conveying Solids

- Oil / Solids Separation (oil well drilling, refining, de-watering)

- Pharmaceutical Refining & Manufacturing

- Industrial & Biological Wastewater Treatment

- Precious Metals Recovery

- Food Processing (olive oil, wine, fruit juice)

- Chemical Refining & Separation

The range of possibilities is not limited to these examples. Our technical and design teams are happy to discuss any requirements and offer advice and suggestions based on our long and successful experience in drive design, operation and maintenance.

Transcyko Centrifuge Drives: The Logical Choice

In business-critical operations such as high-speed centrifuges, cyclo drives offer the most reliable and durable option. Cyclo drives wear evenly with loads shared between components so service intervals can be planned to meet the demands of the business cycle. This minimizes the risk of unexpected failures and expensive stoppages.

At Transcyko we maintain a responsive service team to ensure that your cyclo drives continue to operate smoothly and reliably no matter how harsh or demanding the environment. We also manufacture components that are direct replacements for cyclo drives offered by other manufacturers to keep your business running smoothly.

We offer our customers a one-stop shop for your cyclo drive requirements, no matter how large or how small. Our in-house design and service teams offer rapid and effective global support for all your servicing and maintenance needs.

We are always happy to offer technical advice and assistance at all stages of your business process to ensure you get the best possible drive for your requirements at a cost-effective price. Our customers have discovered that Transcyko cyclo drives are the logical choice and we are the ideal partner to help them achieve and maintain business success. If you would like to find out more about Transcyko centrifuge drives or other product lines please contact us.