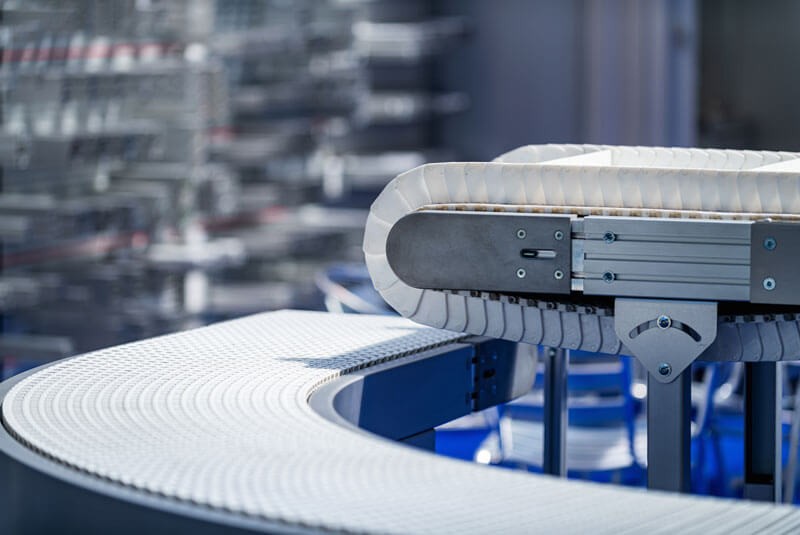

Cycloidal Gearboxes For Conveyor Systems

Cycloidal gearboxes are versatile, compact, powerful and rugged, making them the perfect choice for industrial and commercial conveyor systems. Transcyko cycloidal gearboxes for conveyors match the reliability of cyclo drives to general and customizable conveyor requirements.

Where are cycloidal gearboxes used in industrial & commercial conveyor systems?

- Production lines

- Automated processing conveyors

- Elevators

- Assembly line conveyors

- Steel foundry transport conveyors

- Grain & rice conveyors

- Mining conveyors

- Warehouse conveyors

- Packaging conveyors

- Food processing conveyors

Why are cycloidal gearboxes used for conveyor systems?

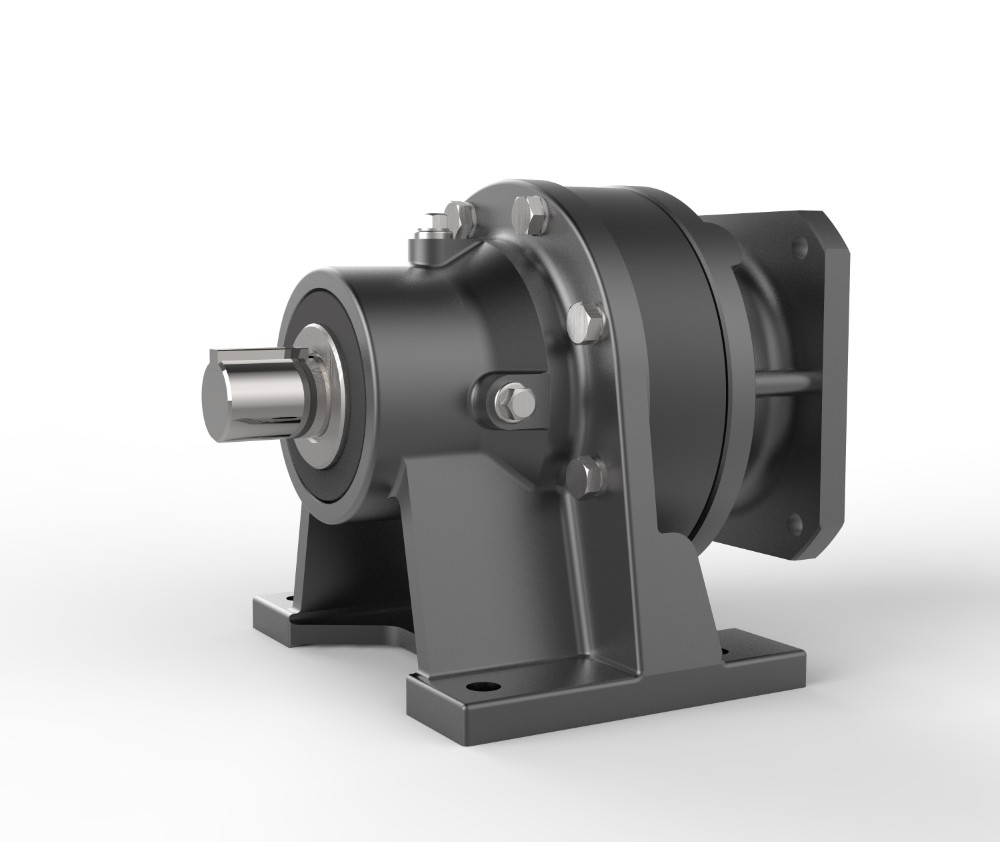

Cycloidal gearboxes, cyclo reducers and derivatives are forms of cyclo drive that are commonly used in conveyor systems. The compact, high torque, easily-sealed, low maintenance configuration of cycloidal gearboxes makes them a good choice for conveyors operating in all conditions, both undercover and exposed to the elements.

Cycloidal gearboxes are perfect for stop-start conveyor systems

Cycloidal gearboxes are also perfectly suited for automated stop-start assembly lines and food processing conveyors, which demand a high degree of positional accuracy. This is because cycloidal gearboxes have the precision and rapid torque management needed to operate as servo motors.

What are examples of cyclo drive servo motor applications?

- Production Line Conveyors

- Automation

- Robotics

- Textile Manufacture

- Food Processing

- Automotive Manufacture

- Parcel Handling

- Laminating Machine

How versatile are cycloidal gearboxes for conveyor systems?

You will find cycloidal gearboxes are the best choice for powering the full range of conveyor systems used in commercial and industrial applications today. Cyclo drives and gearboxes are proving to be the most versatile option for production and manufacturing sites of all sizes.

What are examples of conveyor systems that use cycloidal gearboxes?

- Belt conveyors

- Apron chain conveyors

- Bucket conveyors

- Bucket elevators

- Chain conveyors

- Drag chain conveyors

- Slider bed conveyors

- Screw conveyors

- Magnetic conveyors

- Portable conveyors

- Vibratory conveyors

- Wire mesh conveyors

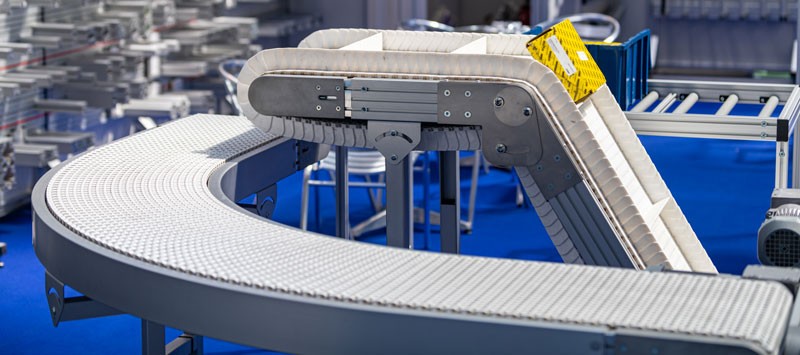

Belt conveyors

Belt conveyors are common material handling machines, with conveyors made of rubber, hinged steel plates or plastic sections. Good for general material handling and used to transport bulk materials such as aggregate, coal, rock, sand, and crushed stone.

Apron chain conveyors

Apron chain and apron pan conveyors are commonly used in paper, demolition debris, cement, sugar, recycling, foundry, lime, stamping, and steel industries where their ruggedness is highly valued.

Bucket conveyors

Bucket conveyors and bucket elevators can be used to move bulk materials up steep inclines, with capacities that can exceed 1,000 tonnes per hour in some applications, requiring powerful and robust drive units.

Chain conveyors

Chain conveyors and drag chain conveyors move bulk materials and heavy items such as pallet loads along channels and troughs. Drag conveyors may include paddles to help move items and materials up inclined surfaces.

Slider bed conveyors

Slider bed conveyors are set up horizontally and are commonly used in packing lines where items are slid on and off the conveyor as it moves.

Screw conveyors

Screw conveyors use a screw principle to push solids, viscous liquids and semi-solids along a channel or pipe. This is usually a demanding application requiring high torque drives.

Specialized conveyors

Specialized conveyor applications include magnetic conveyors, portable conveyors, vibratory conveyors, and wire mesh conveyors

How reliable are cycloidal gearboxes for conveyor systems?

The high reliability of cycloidal gearboxes makes them very attractive for conveyor systems in today’s recessionary markets. Manufacturers and suppliers cannot afford expensive delays from equipment failures and unscheduled maintenance.

Cycloidal gearboxes have predictable and even wear characteristics, so preventative maintenance can be scheduled around busy times. Cycloidal gearboxes and cyclo drives are not subject to unpredictable failures, unlike traditional gearboxes.

Transcyko cyclo drives offer you a worry-free choice for all types of conveyor application. Cycloidal gearboxes and cyclo derivatives offer an efficient go-to standard, reliable drive choice that reduces maintenance costs.

Four reasons to use cycloidal gearboxes for conveyor systems

- Can be used for a wide range of installation types and applications

- Using a small number of standard models minimizes maintenance costs and downtime

- Powerful, compact, drives fit into a smaller footprint than conventional drives

- Cycloidal gearboxes and drive designs are easily sealed and made leak free

How do you specify cycloidal gearboxes for conveyor systems?

For cycloidal gearbox or cyclo drive specification you need to know the required motor horsepower and / or torque at the output shaft. Remember that cycloidal gearboxes are so efficient and load resistant that you can often use a lower HP motor for input power without losing output shaft torque.

What information do I need to specify a cycloidal gearbox?

- Motor horsepower (HP) & speed (RPM)

- Reduction ratio requirement

- Mounting orientation: horizontal, vertical, right-angle, or other.

- Daily hours of continuous operation

- Machinery type to be driven

- Environmental conditions, hazards, contaminants and sealing requirements for construction details

How are service classes defined for cycloidal gearboxes?

AGMA-defined Service Classes are used to rate cycloidal geaboxes for specific operational working conditions and loads. AGMA Service Classifications for gearmotors are: uniform (I), moderate shock (II), and heavy shock (III). These classifications are used to match your product to specific applications.

It is very important to verify AGMA Class requirements for your task to match your drive choices correctly, especially if using non-cyclo gearboxes. Using an AGMA Class I or II planetary gearbox for an AGMA Class III operation will rapidly result in sudden failure.

What are the AGMA classes for conveyor systems?

AGMA Service Classes for conveyors will depend on the loads being carried and requirements for rapid stop-start operation, which increases shock loadings. Many standard conveyors will be AGMA Service Class I, but some will be AGMA Service Class II, to withstand moderate shock loadings. Vertical conveyors carrying substantial bulk loads may be AGMA Service Class III.

Frequently asked questions about cycloidal gearboxes & cyclo drives

Can a cycloidal gearbox withstand severe shock loadings?

Momentary shock loadings of 500% of rating are easily absorbed by cycloidal gearboxes and cyclo drives. By comparison, conventional gearboxes often suffer from component failure at shock loads of 300% of rating. Transcyko can also build customized cycloidal gearboxes and cyclo drives to meet requirements for greater than 500% overload capacity.

What are standard cycloidal gearbox input speeds?

Most cycloidal gearmotors run with input speeds of 1750 and 1165 RPM at 60hz, equivalent to 1450 and 980 RPM at 50Hz. Our technical team will be happy to calculate non-standard input requirements to assess how it will affect gearbox torque and horsepower ratings.

What is the thermal capacity limitation of cyclo drives?

Cycloidal gearboxes usually are not limited by thermal capacity because cyclo drives are almost frictionless. Even when they are working hard, the unique shared internal load design of cycloidal gearboxes significantly reduces thermal loadings.

What inverter turn-down ratios do we offer?

The standard ratio is 10:1 for unbraked motors, we can offer braked motors limited to 4:1 or better depending on power rating. C-face configurations can achieve a 1000:1 ratio.

Transcyko is the one-stop solution for your cycloidal gearboxes, drives & speed reducer needs

We offer our customers the benefits of meeting all their gearbox requirements from us as a single source. Our high performance, reliable, speed reducers, drives, and gearboxes will meet any possible requirement you have. In addition, Transcyko products feature cross-compatibility with other high performance brands for ease of service and maintenance.

- Cycloidal gearboxes

- Cyclo speed reducers & cyclo drives

- Servo, travel motor, and automation gearboxes

- Conventional gearbox solutions & planetary gearboxes

Why is Transcyko the logical choice for all your gearbox, drive & speed reducer needs?

- We are your one-stop provider for all styles of drives, speed reducers, and gearboxes

- We can supply and service parts for other high performance brands

- We offer quick and effective servicer support and maintenance

Contact us today to see how our efficient and reliable cyclo drives can power your conveyor systems. Let us help you add value to your transport and production systems, improving cost leadership and on-site reliability. Our friendly customer service team is ready to provide expert answers to your questions.